Researchers, co-led by ME Assistant Professor Mohammad Malakooti, are creating a device that harvests heartbeat energy to extend battery life in pacemakers.

ME Assistant Professor Mohammad Malakooti

Heartbeats could one day help power something beyond hearts. A pacemaker is a device that helps regulate abnormal heart rates using electrical pulses. Leadless pacemakers, which are placed in the heart and don’t have wires like conventional transvenous pacemakers, are becoming more popular. However, their batteries only last 5 to 12 years, and it’s difficult to retrieve the device when the battery is drained.

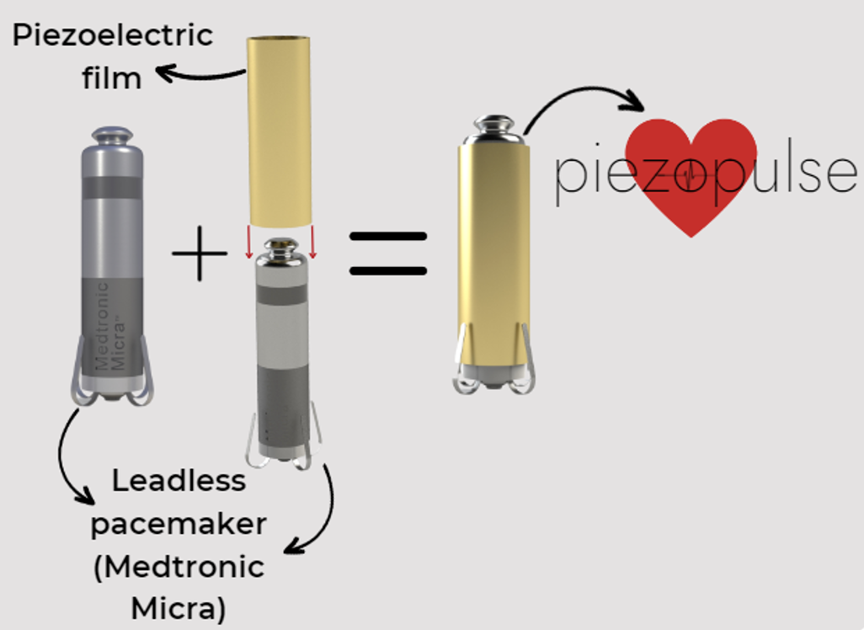

Researchers created a “sleeve” that fits around the pacemaker and is made of flexible piezoelectric materials that harvest the oscillating cardiovascular pressure inside the heart to partially recharge a leadless pacemaker. The project is co-led by ME Assistant Professor Mohammad Malakooti. Early experiments showed that the device could provide about 10 percent of power required for pacing. As the interdisciplinary team from ME, bioengineering and UW Medicine continues their work, Malakooti shares how the device was created and its potential to improve leadless pacemakers’ battery life.

Tell us about the project and the early findings.

The device is designed to surround a leadless pacemaker, such as the Medtronic Micra, which sits in the heart’s right ventricle. The challenge with a leadless pacemaker is that it runs out of battery and it’s hard to retrieve. A second device is often implanted without removing the first one.

Our innovation involves the use of energy harvesting to extend the leadless pacemaker’s battery life. We do this by creating a sleeve for a pacemaker using piezoelectric materials, which generate electricity when mechanical pressure is applied. The way we are incorporating the piezoelectric materials inside the heart is new. Previously, researchers placed flexible piezoelectric films on the external surface of the heart to harvest the mechanical energy from heartbeat for a transvenous pacemaker. This is not practical and could cause complications since it requires an additional open-heart surgery, which cardiologists and patients want to avoid.

In our experiments, we placed the pacemaker with the sleeve inside a machine that simulates blood pressure in the right ventricle. The compressive force from simulated blood pressure causes mechanical deformations in the outer layer of the sleeve, which produces electric voltage for every cycle of the heartbeat — enough to increase the battery life by 10 percent. We still have work to do to boost the battery life more than 10 percent and further validate our findings, but the potential is indeed very exciting.

UW researchers created a sleeve for a pacemaker using piezoelectric materials, which generate electricity when mechanical pressure is applied. Image courtesy of iMatter Lab and BioE

How did your team come up with the materials to use and the initial design of the device?

The device is very small, about one-third of an AAA battery. The challenge is to keep its size and shape to maintain the same implantation procedure while making sure it can generate sufficient energy. Our team chose to use piezoelectric polymers because of their stability, biocompatibility, and mechanical flexibility. Common piezoceramics, like lead zirconate titanate, were excluded from consideration due to their toxicity, brittleness which could lead to fracture, and complex 3D fabrication.

We specifically selected a polymer called polyvinylidene fluoride (PVDF) for its large piezoelectric response, in addition to its biocompatibility. The material is rolled into a cylindrical shape that matches the leadless pacemaker, creating a flexible piezoelectric housing. The prototype created by the BioE students includes an aluminum rod as a substitute for the actual pacemaker, insulator films, and epoxy to encapsulate it. We decided on a dumbbell-shaped design because we don’t want to fix the PVDF film directly on the pacemaker. This innovative design allows for more deformation under applied pressure, resulting in enhanced energy harvesting.

Why is this research significant to you?

It applies to a real problem, which is challenging but very exciting. The goal is to prolong battery life, reduce reimplantation and increase leadless pacemaker candidacy. If there are fewer battery replacements needed, leadless pacemakers could be more accessible for younger patients.

I also get to revisit some of my previous research. My Ph.D. focused on multifunctional composites with embedded piezoelectric materials. This involved the synthesis of piezoelectric nanomaterials and polymers, composite fabrication, theoretical and numerical modeling, and electromechanical characterizations.

What’s next for this project?

Last year we worked with a talented group of bioengineering students in the Master’s of Applied Bioengineering program. I’m excited to co-mentor a new group of students and continue collaborating with Dr. Babak Nazer, associate professor of medicine at UW Medicine and director of the Translational Electrophysiology Laboratory. We are conducting more basic research such as multiphysics modeling of flexible piezoelectric structures to enhance the energy harvesting performance. We will test our designs with new prototypes and use different materials to make the device more sensitive and responsive to the oscillating blood pressure. Then, Dr. Nazer at UW Medicine will do in-vivo validation to confirm safety and efficiency. This will lead to new insights for implantable piezoelectric energy harvesters and our hope is to have a device that partially powers a leadless pacemaker.

Originally published February 12, 2024