November 3, 2021

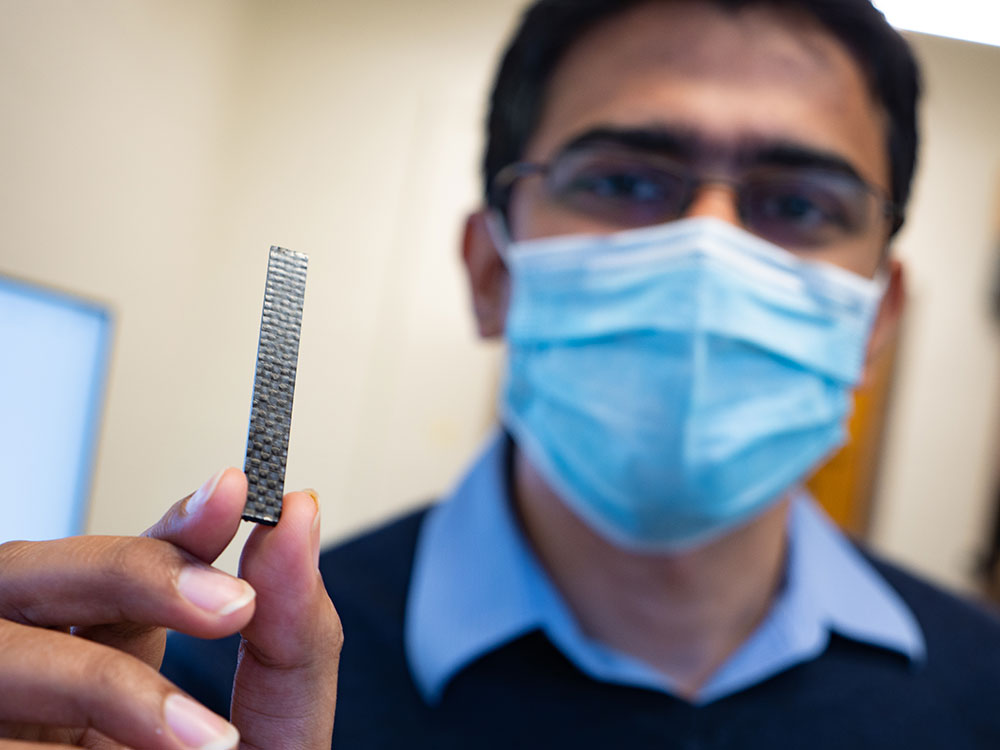

ME Assistant Professor Aniruddh Vashisth holds a sample of a healable carbon fiber composite material that his team is studying. Photo by Andy Freeberg / University of Washington

Because of their high strength and light weight, carbon-fiber-based composite materials are gradually replacing metals for advancing all kinds of products and applications, from airplanes to wind turbines to golf clubs. But there’s a trade-off. Once damaged or compromised, the most commonly-used carbon fiber materials are nearly impossible to repair or recycle.

Related story

Materials & Manufacturing

How Washington became a global epicenter for advanced carbon fiber

Stronger than steel and lighter than aluminum, carbon fiber composite materials are one of the key enabling technologies of the 21st century and play a particularly important role in Washington.

In a paper posted this week in the journal Carbon, a research team that includes UW mechanical engineering Assistant Professor Aniruddh Vashisth describes a new type of carbon fiber reinforced material that is as strong and light as traditionally used ones but can be repeatedly healed with heat, reversing any fatigue damage and providing a way to break it down and recycle it when it reaches the end of its life.

“Developing fatigue-resistant composites is a major need in the manufacturing community,” says Vashisth. “In this paper, we demonstrate a material where either traditional heat sources or radio frequency heating can be used to reverse and postpone its aging process indefinitely.”

The material is part of a recently developed group known as carbon fiber reinforced vitrimers (vCFRP). The materials typically used today, whether in sporting goods or aerospace, are carbon fiber reinforced polymers (CFRP).

Traditional CFRPs typically fall into two categories: thermoset or thermoplastic. The “set” variety contains an epoxy, a glue-like material where the chemical links holding it together harden permanently. The “plastic” version contains a softer type of glue so it can be melted back down and reworked, but this becomes a drawback for high strength and stiffness. Vitrimers on the other hand, can link, unlink and re-link, providing a middle ground between the two.

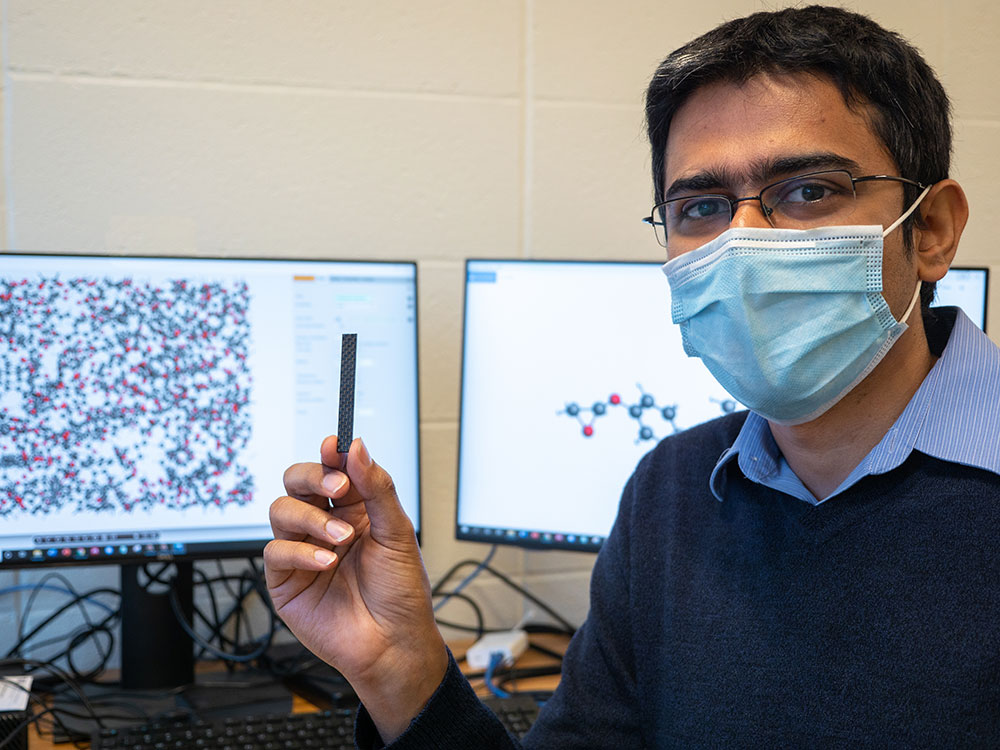

“Imagine each of these materials is a room full of people,” says Vashisth. “In the thermoset room all of the people are holding hands and won’t let go. In the thermoplastic room people are shaking hands and moving all around. In the vitrimer room people shake hands with their neighbor but they have the capacity to exchange handshakes and make new neighbors so that the total number of interconnections remains the same. That re-connection is how the material gets repaired and this paper was the first to use atomic-scale simulations to understand the underlying mechanisms for those chemical handshakes.”

Vashisth used atomic-scale simulation software (seen on the monitors in the background) to help understand the underlying mechanics of the healable vitrimer. Photo by Andy Freeberg / University of Washington

The research team believes vitrimers could be a viable alternative for many products currently manufactured from thermosets, something badly needed as thermoset composites have begun piling up in landfills. The team says that healable vCFRPs would be a major shift toward a dynamic material with a different set of considerations in terms of life-cycle cost, reliability, safety and maintenance.

“These materials can translate the linear life cycle of plastics to a circular one, which would be a great step towards sustainability” says Nikhil Koratkar, the John A. Clark and Edward T. Crossan Professor of Mechanical, Aerospace and Nuclear Engineering at Rensselaer Polytechnic Institute (RPI) and one of Vashisth’s co-authors on the new paper.

In addition to Koratkar and Vashisth, the research team also included Mithil Kamble and Professor Catalin Picu of RPI, and Hongkun Yang and Professor Dong Wang of the Beijing University of Chemical Technology.

Written by Andy Freeberg

For more information, contact Vashisth at vashisth@uw.edu or Koratkar at koratn@rpi.edu.

Find out more

The new research paper, “Reversing fatigue in carbon-fiber reinforced vitrimer composites” is available from Carbon.

The UW is a leader in advanced composites research and education. Read How Washington became a global epicenter for advanced carbon fiber or visit the Advanced Composites Center website to learn more.