Photos by Matt Hagen

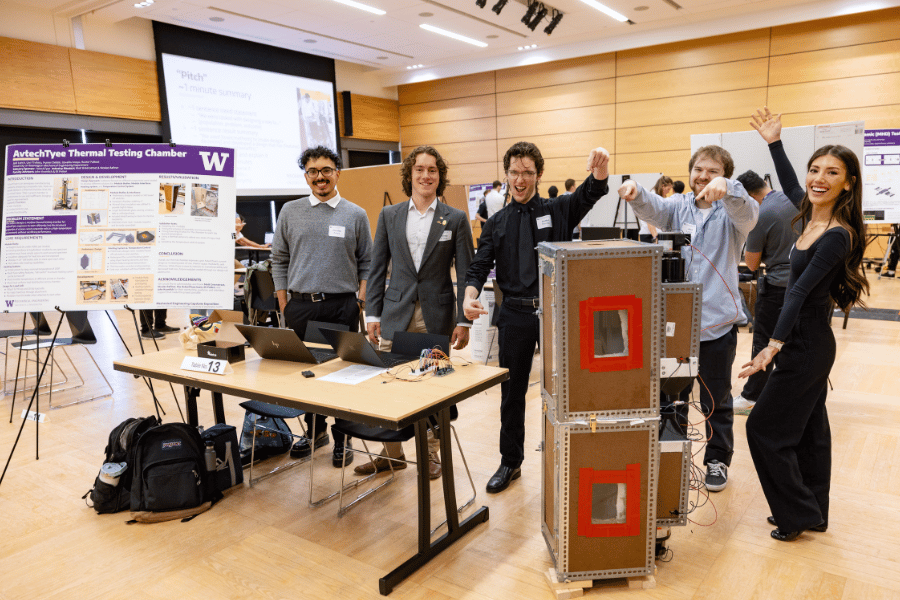

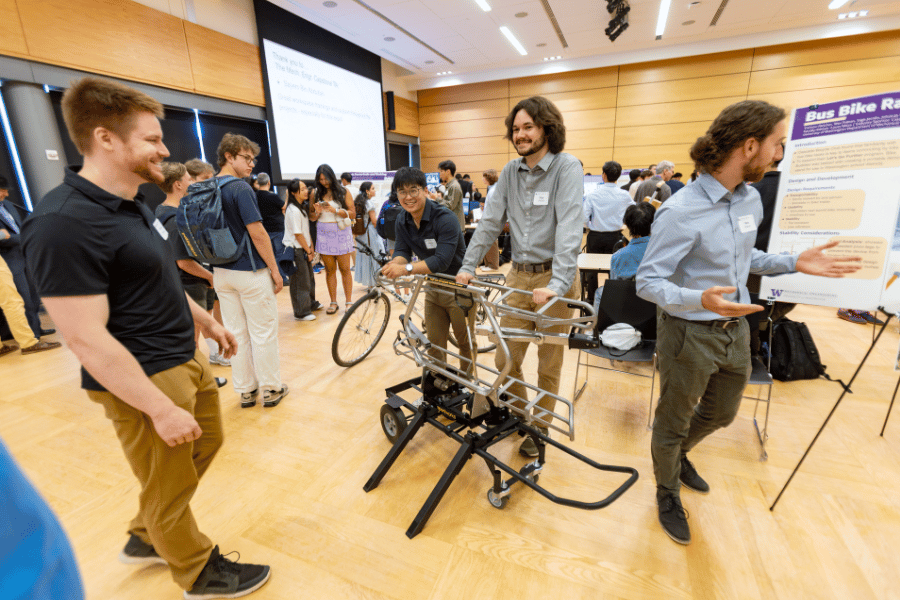

At the 2025 ME capstone expo, students showcased their capstone senior design projects — the culmination of their undergraduate education. Projects ranged from a modular thermal test chamber for composite parts to drone boats for automated water quality measurements.

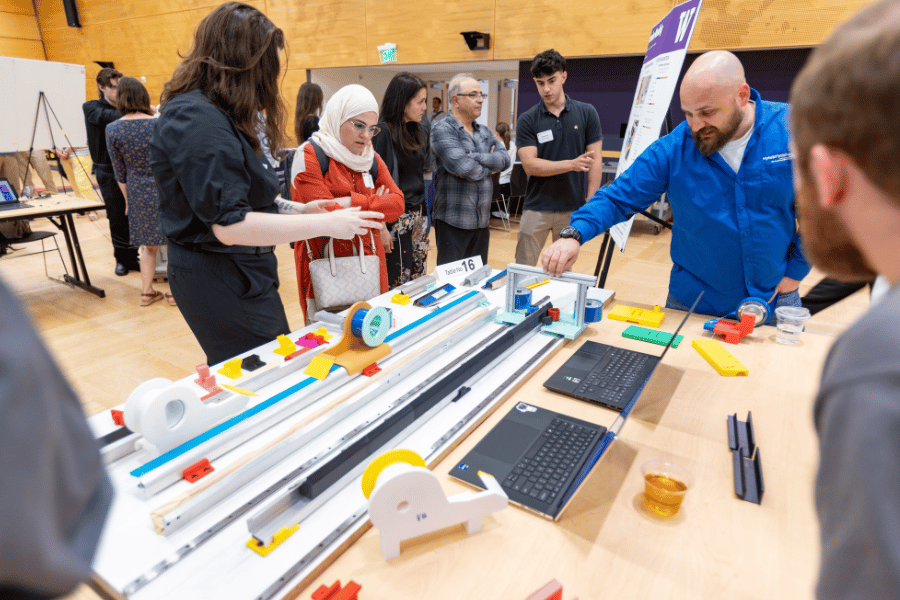

A team that created a tape masking system displays their prototypes at the capstone expo.

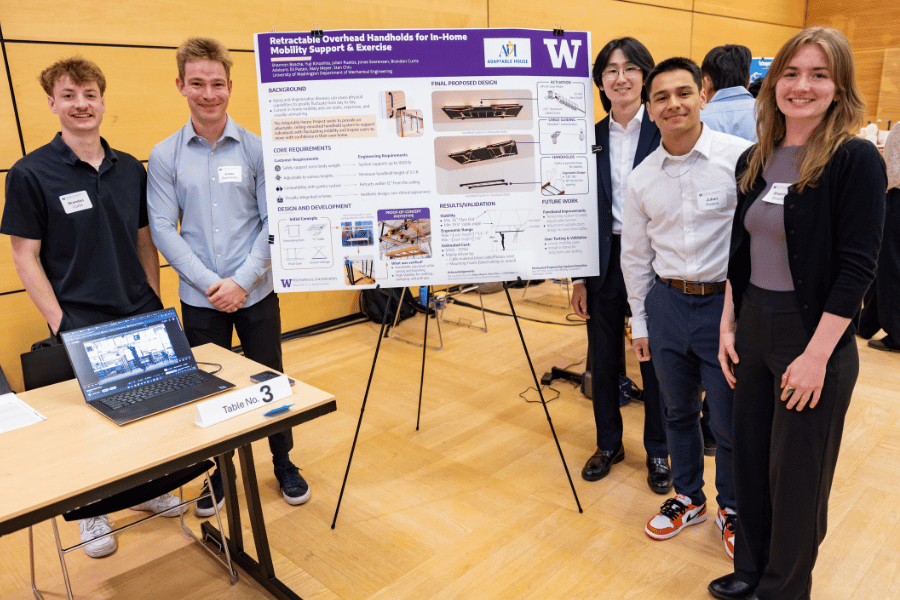

ME seniors displayed their prototypes and posters, which provide recommendations for tackling real-world engineering problems, to industry members, alumni, faculty, staff and other students. Capstones were sponsored by local companies, community organizations, national labs, UW research labs and more. Students and student clubs also initiated several projects this year.

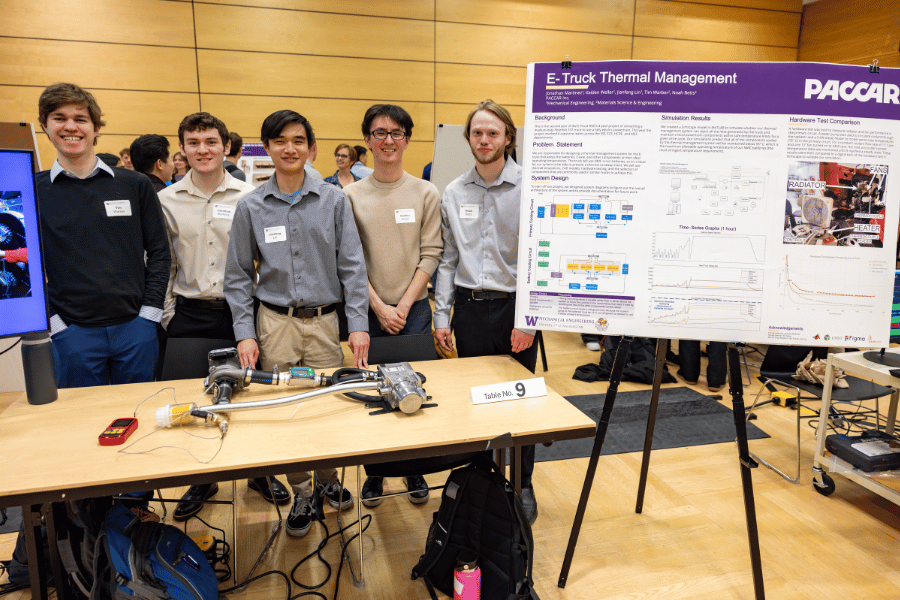

A capstone team, as part of the E-Truck club, designed and simulated a thermal management system.

“We’re really proud of the diverse types of needs that students are able to address in our program,” says Assistant Teaching Professor and Capstone Director Eli Patten. “Many projects this year had an ambitious scope, and the students really stepped up. The level of iteration, testing and functionality of final deliverables keeps increasing every year."

Hytek Finishes sponsored a team that created a tape masking system for their workers to prepare aerospace components for painting, which is currently done by hand. The students met their goals of improving worker comfort and reducing process time.

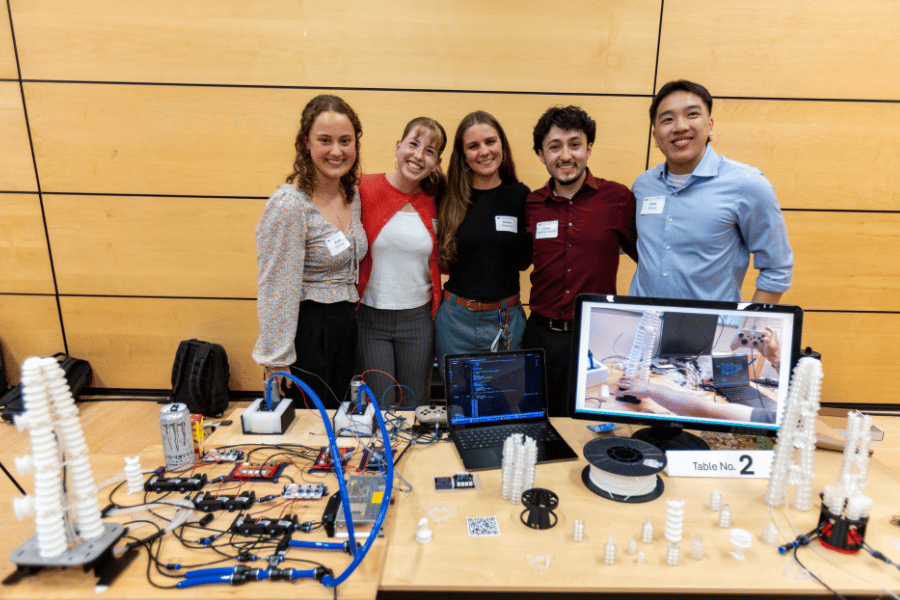

A student team developed soft 3D-printed robotics with versatile capabilities, inspired by the flexibility of an octopus.

Another team, as part of the E-Truck club, designed and simulated a thermal management system for the diesel truck provided by PACCAR that they’re working to convert into an electric vehicle. This team’s goal was to maintain ideal temperature ranges for the truck components under various operating conditions in Western Washington. This is especially important for the truck’s batteries. The team’s simulation and initial testing predicted that the components they selected would keep them below their maximum allowable operating temperature.

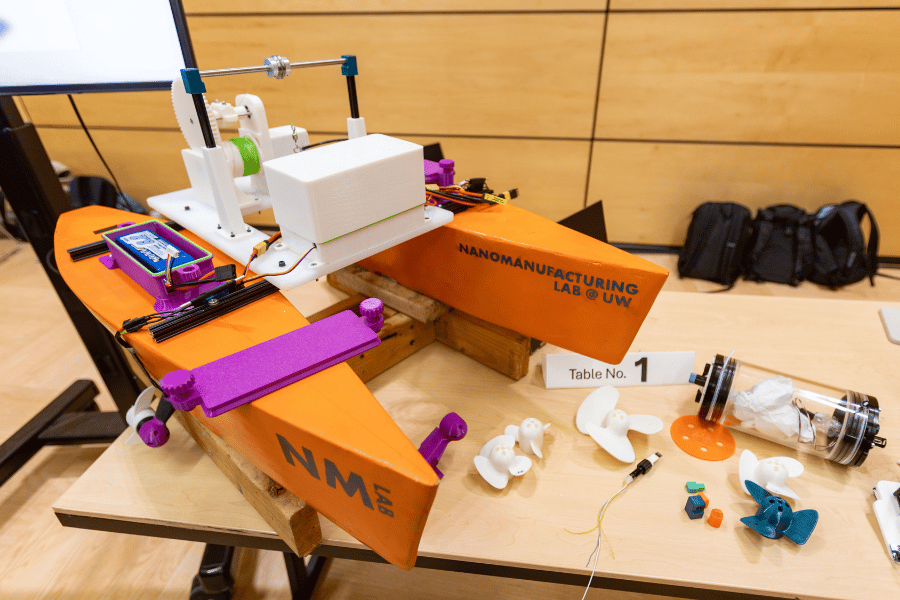

Students worked with the Applied Physics Laboratory at the UW to develop soft 3D-printed robotics with versatile capabilities, inspired by the flexibility of an octopus. The team, which received the Best Design award at the capstone expo, also applied their work to an industry setting. They created a flexible wrist that can bend in multiple directions and sense what it’s gripping for Amazon Robotics, which is interested in using soft robotics in their warehouses to access objects in areas difficult for traditional rigid robots to reach.

A team of ME and materials science and engineering students developed a hydrogen-powered model submarine.

“I have done research in biomechanics, which works on biological problems using the core principles of mechanical engineering, but this was my first time drawing direct biological inspiration for a design from an animal,” says Melanie Bakin (BSME '25). “It was exciting to work on novel robotics that could shape the future and serve society's real-world needs.”

Interdisciplinary teams included a group of ME and materials science and engineering (MSE) students who developed a hydrogen-powered model submarine. Through the environmentally friendly propulsion system they developed, aluminum reacts with water to produce hydrogen and generate thrust. The prototype produced hydrogen for more than 30 minutes in their final testing.

Originally published July 7, 2025