The Composite Shop provides a space for layups and access to cutting equipment, heated appliances, vacuum pumps, and hand tools.

Shop access

What do I need to do before using the Composite Shops?

- Register for ME CORAL with your Worktag, course, or other billing info. All users must register.

- Attend an in-person shop safety training. Fill out the Composite Shop orientation interest form.

- After attending the in-person training, complete the following:

Rates

An hourly rate is charged for the time each user spends working in the shop. For some equipment, an additional hourly rate is charged for the time it is being used. Some consumable vacuum bagging materials are available to purchase in single "kit" quantities.

| Category | Rate Base | Internal Rate | External Rate | Outside Academic Rate |

| Shop access | hour | $23 | $67 | $27 |

| Autoclave | hour | $12 | $71 | $13 |

| CNC fabric cutter | hour | $14 | $74 | $16 |

| Large oven | hour | $23 | $67 | $26 |

| Vacuum bag kit | sample | $43 | $96 | $49 |

| Lab engineer | hour | $99 | $173 | $115 |

Location

Room G032A on the ground (G) floor of the Mechanical Engineering Building (MEB).

Scheduling

Some equipment may be reserved in CORAL. Before using reservable equipment for the first time, please contact the shop manager to schedule machine-specific training.

Equipment

A composite curing autoclave is a pressurized convection oven. The temperature can be increased and decreased at a controlled rate. Compressed air is used to consolidate your laminate against a mold or tool surface. A vacuum pump removes air from your vacuum bags to prevent voids.

Specifications

- 400 °F max. temperature

- 10 °F per minute max. heating rate

- 3 °F per minute max. cooling rate

- 10 to 89 psi air pressure

- 29.5 in. Hg. vacuum

- 3 vacuum bag connections

- 3 vacuum transducers; separate bag connection required

- 3 part thermocouples; lead/lag control capable

- Interior dimensions: Dimensioned drawing

Reserve the autoclave in CORAL before using. Please bring a cure recipe with pressure and temperature setpoints, ramp rates, and soak times. All new materials and cure recipes must be approved by a lab engineer.

Press consolidation uses flat, parallel steel platens to apply uniform pressure with even temperature control across the platen surfaces. A separate tool surface must be used to prevent damage to the platens; flat aluminum plates are available to use as tooling for flat parts.

Specifications

- Model: Wabash Genesis

- 650 °F max. temperature

- Platen dimensions: 24 in. by 24 in.

- 1 ton (2,000 lbs.) to 50 tons force

Reserve the platen press in CORAL before using. Please bring a cure recipe with pressure and temperature setpoints, ramp rates, and soak times. All new materials and cure recipes must be approved by a lab engineer.

Reinforcement fabric, both dry fiber and uncured thermoset prepreg, can be cut using this computer-controlled cutting table, which features a downdraft vacuum to hold material in place. Precise shapes and fiber angles may be achieved in almost any material you can cut with scissors. This machine cannot cut through cured composite laminates; look for abrasive cutting equipment available in the other ME shops.

Specifications

- Model: Autometrix Advantage

- Cutting area: 94 in. by 63 in.

- Cutting tool: 28 mm rotary blade

- Minimum cutting radius: 14 mm

- Plotting (drawing) tool: Sharpie fine-point marker

- Software (provided): PatternSmith 10

- File types for import: .dxf (preferred), .aam, .cmd, .gbr, .pdf

Reserve the CNC fabric cutter in CORAL before using. Please bring a dimensioned sketch of your cuts or prepare a digital cut file using one of the file types listed above. All new materials must be approved by a lab engineer.

Ultrasonic leak detection devices are available for locating air leaks in your vacuum bags.

Distran Ultra CE Ultrasonic Camera

- Handheld camera visualizes the location of air leaks

- Min. detection range: 1 ft

- Max. detection range: 10 ft typical, up to 165 ft

- Gases detected: vacuum and compressed air only

Superior AccuTrak Ultrasonic Leak Detector

- Model: AccuTrak VPE 3rd generation

- Gases detected: vacuum or any compressed gas

- Converts ultrasonic noise to 0 Hz to 4 kHz sound audible through headphones

Besides the shop access rate, there is no additional charge to use these devices in the ME Composite Shop. They may be used anywhere on campus while under the supervision of an ME lab engineer at the associated hourly rate.

This linear press can weld thermoplastics, non-wovens, and some metals using pressure and high-frequency vibrations applied through a sonotrode.

Specifications

- Model: Telsonic Ultrasonics USP3000

- Sonotrode frequency: 20 kHz

- Sonotrode diameter: 10 mm

- Height adjustment: 250 mm

- Stroke of weld (linear pneumatic piston): 100 mm

- Peak power: 2.4 kW

- Welding force: 2.5 kN

- Working area: 420 mm by 415 mm

Two mechanical convection lab ovens are available with different capacities and capabilities.

Small Oven

- Model: Blue M ESP-400C-5

- Interior dimensions: 19 in. wide by 15 in. deep by 18 in. high

- Max. temperature: 500 °F

- Fixed temperature control with manual cooling

Large Oven

- Model: Blue M POM-246-F

- Interior dimensions: 36 in. wide by 24 in. deep by 48 in. high

- Max. temperature: 600 °F

- Programmable ramp rate and soak time with manual cooling

- Vacuum pump available

Reserve an oven in CORAL before using. Please bring a cure recipe with temperature setpoints, ramp rates, and soak times. All new materials and cure recipes must be approved by a lab engineer.

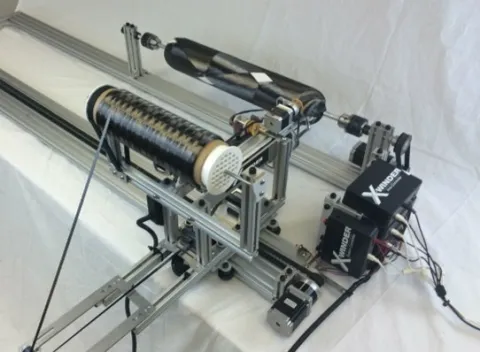

Rotationally symmetric mandrels can be wrapped with a reinforcement fiber tow dipped in epoxy resin and laid at precise fiber angles. The software can generate tow path plans for cylindrical tubes, tapered profiles, stepped joints, and flat and hemispherical closed ends.

Specifications

- Model: X-Winder 4X-23

- Max. mandrel diameter: 8 in.

- Max. mandrel length as configured: 22 in.

- Mandrel length is expandable up to 80 in.

Besides the shop access rate, there is no additional charge to use this equipment.

Thermoplastic sheets can be heated, formed over a mold, and vacuum applied to achieve a high level of detail.

Specifications

- Model: Formech 450DT

- Standard forming area: 11 in. by 17 in.

- Reduced forming areas: 5 in. by 5 in. and 11 in. by 11 in.

- Max. depth of draw: 6.3 in.

- Max. material thickness: 0.2 in.

- Mold release method: air pressure

Besides the shop access rate, there is no additional charge to use this equipment.

Freezer storage is available for epoxy prepreg which will be used in the ME Composite Shop; storage is only available to individuals and groups who are working on their projects in the shop. Temperature maintained between -10° F and 10° F.

Please contact the shop manager to discuss freezer space availability before you purchase or receive any material requiring cold storage. Storage space is never guaranteed.