The Mechanical Test Lab has facilities for static load testing, cyclic fatigue testing, and a drop tower for impact testing. Also available are a variety of extensometers, load cells, and grips.

Lab access

What do I need to do before using the shops?

- Register for ME CORAL with your Worktag, course, or other billing info. All users must register.

- Contact mechtest@uw.edu for individual Test Lab training.

- Complete the Mechanical Test Lab quiz after attending the in-person training.

Rates

Equipment has hourly rates, and strain gage kits are available to purchase for use in the test lab.

| Category | Rate Base | Internal Rate | External Rate | Outside Academic Rate |

| Semi-static load frame | hour | $46 | $168 | $53 |

| Fatigue frame | hour | $53 | $177 | $61 |

| Drop tower | hour | $48 | $171 | $55 |

| Strain gage kit | sample | $40 | $75 | $46 |

| Lab engineer | hour | $99 | $173 | $115 |

Hours

The test lab is typically staffed Monday through Friday from: 9 a.m. to 5 p.m. Availability varies depending on scheduled lab classes and safety classes which are typically in the afternoons between 2-5 p.m.

Location

Room 127 in the Mechanical Engineering Building (MEB).

Scheduling

Reserve equipment in CORAL before using. Please email mechtest@uw.edu to schedule training before using equipment for the first time.

If you need assistance with fixtures or other aspects of your setup, please contact mechtest@uw.edu at least 24 hours in advance of your appointment. When deciding how much time your tests will take, please allow for adequate time to install and remove your fixtures.

Equipment

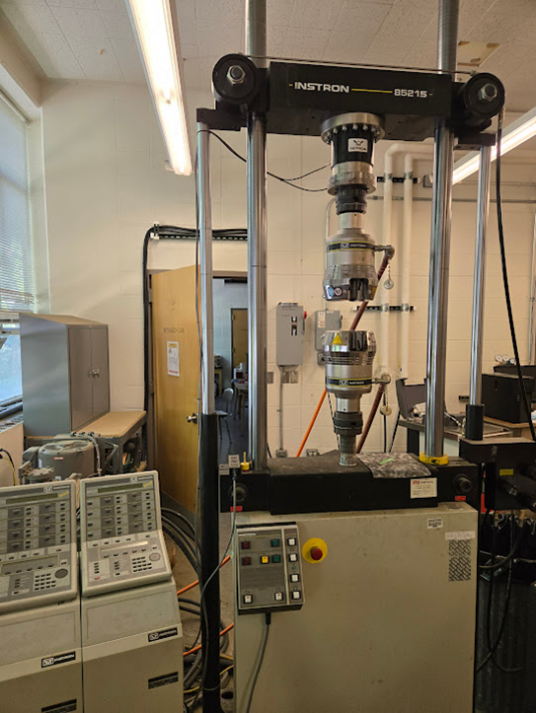

For quasi-static load testing in Tension and Compression. Block programmable for low-frequency (< 1 Hz) cyclic testing. Bluehill 3 control and data acquisition software. Contact the lab engineers about the appropriate fixtures for your project.

- Load Cells: 250 kN, 50 kN, 2 kN, and 50 N

- Wedge Grips: flat and round specimens

- Flexure: 3pt. and 4pt. bend fixtures

- Compression Platens: various

- ASTM Fixtures for Composites:

- D3410 IITRI Compression

- D5379 Iosipescu Shear

- D5961 Laminate Bearing Strength

- D6484 Boeing Open-Hole Compression

- Extensometers:

- Video (non-contacting), axial and transverse

- Axial clip-on (2), 25mm, 50mm gauge lengths

- Transverse clip-on, 12mm max. gauge length

- 2-D Digital Image Correlation (DIC Replay)

- Strain Gauge DAQ: 20 channels

- Various custom fixtures

Instrumented drop tower captures and records impact events, directly measuring impact force, velocity at impact, and elapsed time. Calculated results include impact energy and deflection. Instron Impulse™ software is used for control, data acquisition, and analysis. Integrated environmental chamber for testing down to -40°C (liquid nitrogen required).

- Load cell (Tup) capacity: 15kN

- Energy range: 4.6 – 826 Joules

- Maximum impact velocity: 20 m/sec

- Drop weights: 2.7 – 14.7 kg

- Data: 8192 points at up to 1.17 MHz

- Fixture: ISO 6603-2

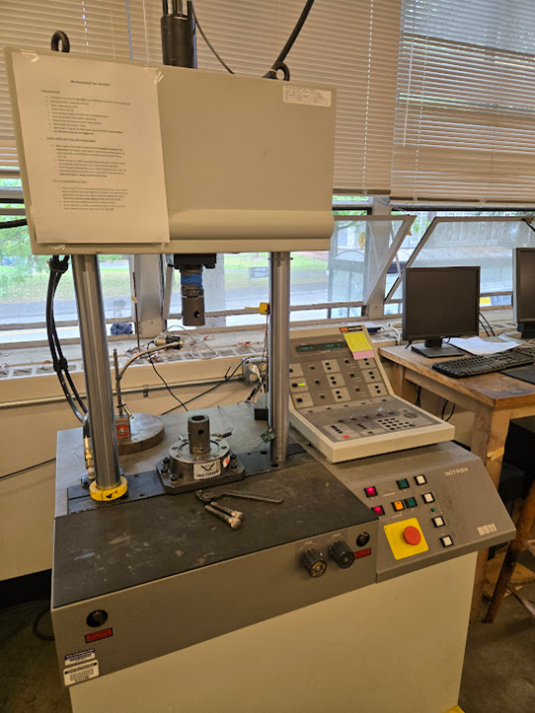

For cyclic testing.

- Axial loads up to 20 kN

- Mechanical wedge grips

- C(T) fracture fixtures

- 10 Hz maximum cycle rate

For axial and torsional cyclic testing.

- Axial loads up to 100 kN

- Torsional loads up to 1000 N-m

- Hydraulic grips

- 20 Hz maximum cycle rate