Mechanics of materials involves investigating how and why materials bend, deform, carry loads and break when subjected to forces or other environmental conditions — and how to make materials tougher and more resistant to damage by changing their structures.

This area of study is behind almost every branch of ME requiring high-performance materials, such as making aircraft materials lighter yet stronger, developing tougher sustainable materials, promoting tissue regeneration after injury, creating more effective sensors, and designing long-lasting materials for biomedical implants, batteries and more.

How ME is making an impact

Shaping the future of recyclable electronics

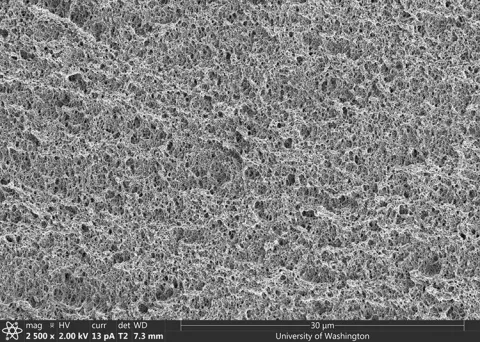

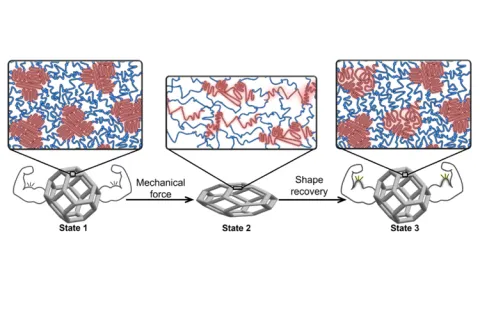

Many industries rely on polymer foam materials because they are inexpensive, lightweight, insulating and energy-absorbent. Assistant Professor Mohammad Malakooti’s lab is researching an innovative manufacturing method for selective foaming of polymers and composites.

Creating tougher sustainable materials

Assistant Professor Lucas Meza is studying how to create tough, sustainable materials using nanoengineering.

Engineering heart health

Professor Nate Sniadecki approaches the heart from a biomechanical perspective, designing and developing micro- and nano-sized tools that measure the resilience of heart cells.

A tiny break into toughness

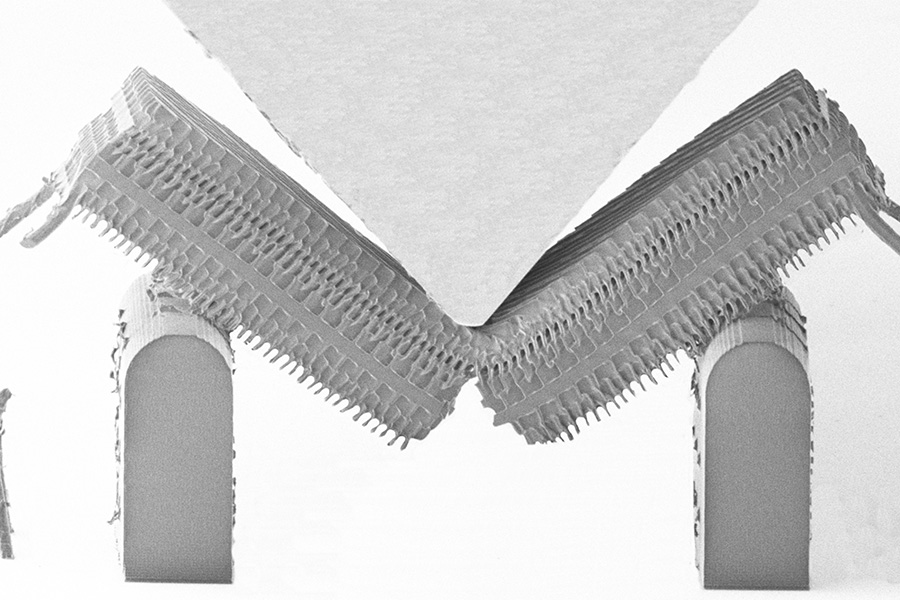

The Meza Research Group investigated how tiny nanostructured materials found in nature make materials resistant to breaking. The research sheds light on how methods like reducing fiber size and increasing fiber twist can improve durability.

Research centers and institutes

Advanced Composites Center

The Advanced Composites Center is building a robust innovation ecosystem for industry and academia to advance the field of data-driven methods for composites manufacturing.

Boeing Advanced Research Collaboration

Through the Boeing Advanced Research Collaboration, Boeing-employed affiliate instructors work in the lab side by side with faculty and students on joint research projects in the manufacturing and assembly of aircraft and spacecraft structures.

Clean Energy Institute

The Clean Energy Institute accelerates the adoption of a scalable and equitable clean energy future that will improve the health and economy of our state, nation and world.

Institute for Nano-Engineered Systems

The Institute for Nano-Engineered Systems accelerates the translation of nanoscale research into next-generation products for quantum information sciences, clean energy and medical diagnostics.

Associated faculty

Notable partners and sponsors

Blue Origin, Boeing, Intel, Medtronic, Meta, Microsoft, NASA, National Science Foundation, Oak Ridge National Laboratory, PACCAR, Pacific Northwest National Laboratory, U.S. Department of Defense, U.S. Department of Energy.

Application areas

Advanced manufacturing

Mechanics of materials informs the manufacturing and maintenance of high-performance materials for aircraft, microelectronics and more.

Biomedical science and technology

Understanding the mechanics of materials helps researchers develop medical devices and investigate the human body from a biomechanical perspective.

Energy

Knowledge of the mechanics of materials helps researchers create energy-harvesting materials, build longer-lasting batteries and renewable energy devices, and more.

Environment

Our researchers are investigating how to create tougher, more sustainable materials, as well as using materials to capture carbon emissions. Many of our researchers take inspiration from how nature engineers itself at the micro- and nanoscale.

Robotics

Understanding the mechanics of materials can help researchers advance robotics.