ME researchers study or design dynamical systems that are constantly moving and changing – such as mechatronics systems that integrate mechanics, electronics and computing.

Mechatronics control systems include sensing and feedback to adjust the physical action of a robot, a car, or an air conditioning unit, for example. Much of the mechatronics work takes place in robotics; our faculty are leading research in robot-human interaction, sensing and automation. Robotics enables researchers to see artificial intelligence (AI), controls and machine learning models in action.

How ME is making an impact

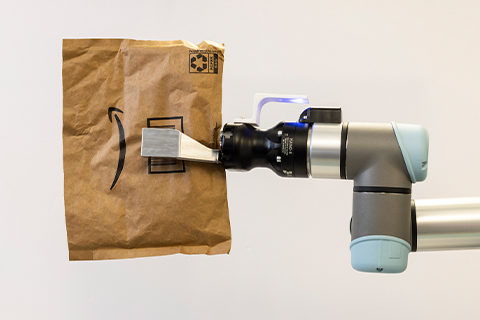

Robotics for manufacturing

Working alongside industry partners, ME researchers are exploring ways to improve manufacturing workers’ safety, automate inspections and enhance robots’ abilities to interact with objects around them.

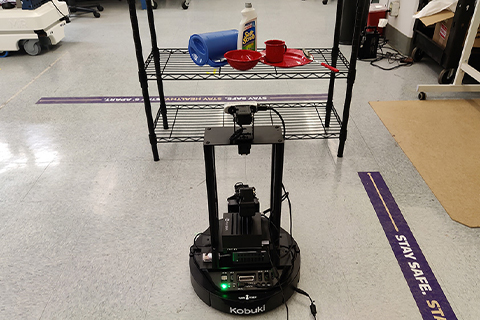

Human-inspired robotic perception

ME Ph.D. graduate Ekta Samani’s research aims to improve visual perception in autonomous robots.

To improve robots, look to birds

ME researchers improved a mathematical model describing how birds flock together – which could be applied to build robots that move in the same way.

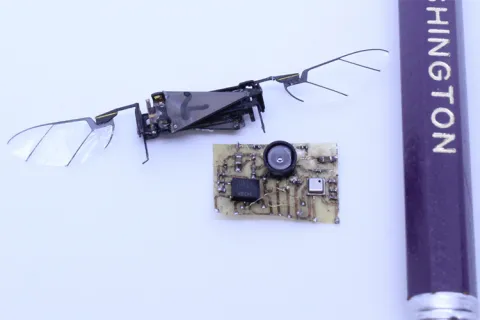

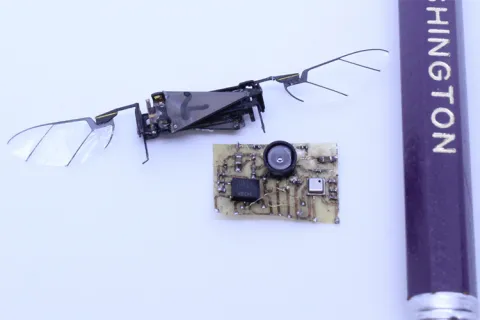

A new sensor system for insect-sized robots

Researchers have developed the lightest avionics system yet for flying insect robots — a step toward documenting the lightest vehicle capable of sustained hovering.

Research centers and institutes

Advanced Composites Center

The Advanced Composites Center is building a robust innovation ecosystem for industry and academia to advance the field of data-driven methods for composites manufacturing.

AI Institute in Dynamic Systems

The AI Institute in Dynamic Systems aims to develop the next generation of advanced machine learning tools for controlling complex physical systems by discovering data-driven models through optimal sensor selection and placement.

Boeing Advanced Research Collaboration

Through the Boeing Advanced Research Collaboration, Boeing-employed affiliate instructors work in the lab side by side with faculty and students on joint research projects in the manufacturing and assembly of aircraft and spacecraft structures.

Center for Limb Loss and MoBility (CLiMB)

Center for Limb Loss and MoBility (CLiMB) partners with the UW and ME department to enable students and faculty to carry out biomechanics research that aims to preserve and enhance the mobility of veterans and others with lower limb musculoskeletal impairment or limb loss.

Associated faculty

Notable partners and sponsors

Advanced Robotics for Manufacturing (ARM) Institute, Amazon, Boeing, GKN Aerospace, National Science Foundation, U.S. Department of Defense, U.S. Department of Energy.

Application areas

Advanced manufacturing

Researchers apply their knowledge of dynamical systems and mechatronics to automate the assembly of aircraft parts, improve employees’ safety and assist with tasks such as inspection or sanding.

Biomedical science and technology

ME researchers use their knowledge of controls to improve prosthetic devices, study how robotic devices can help with rehabilitation training and more.

Environment

Our researchers are exploring how tiny robots can be used for environmental monitoring, such as monitoring crops or identifying gas leaks.

Robotics

ME leads research in robot-human interaction and has created robots that assist with various tasks.