UW Mechanical Engineering is helping to advance materials and manufacturing and strengthen the innovation ecosystem in the State of Washington and the nation. Washington is at the forefront of advanced manufacturing — using technology to improve products, services and processes.

It has a growing health technology and medical device industry, as well as the most robust aerospace cluster in the world. Next-generation materials and systems will be knowledge-intensive and will require innovations that leverage emerging information and sensing technologies. The new processes and solutions being developed in our labs are helping to create a stronger, more sustainable, globally competitive manufacturing sector.

Key research areas

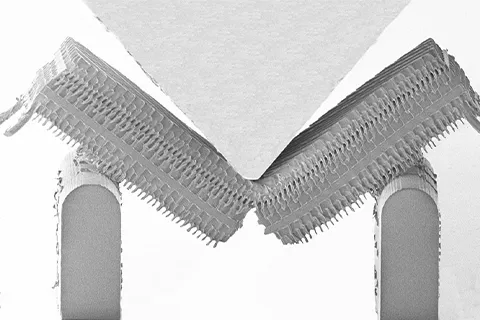

- Additive and digital manufacturing

- Advanced composite materials and structures

- Biomanufacturing

- Fracture mechanics and fatigue

- Machine learning and big data

- Modeling, simulation and sensors

- Nanotechnology

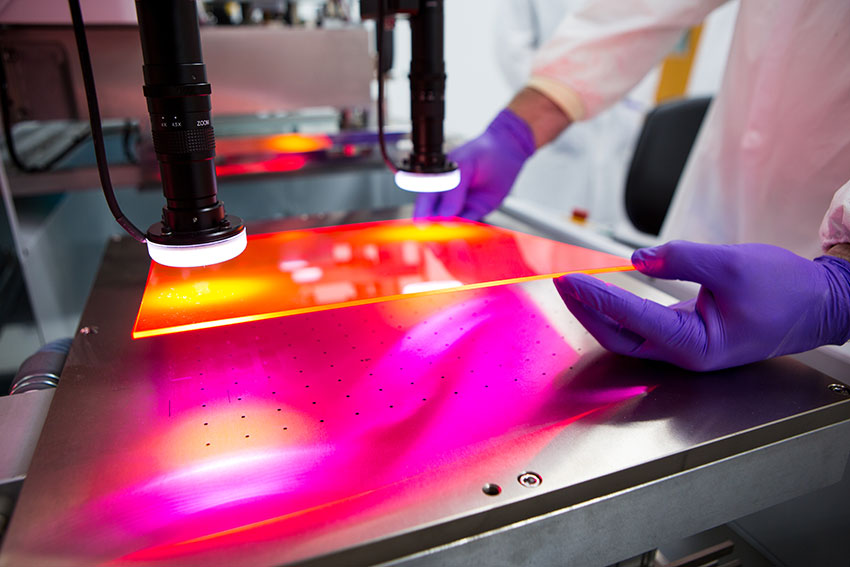

- Printed and flexible electronics

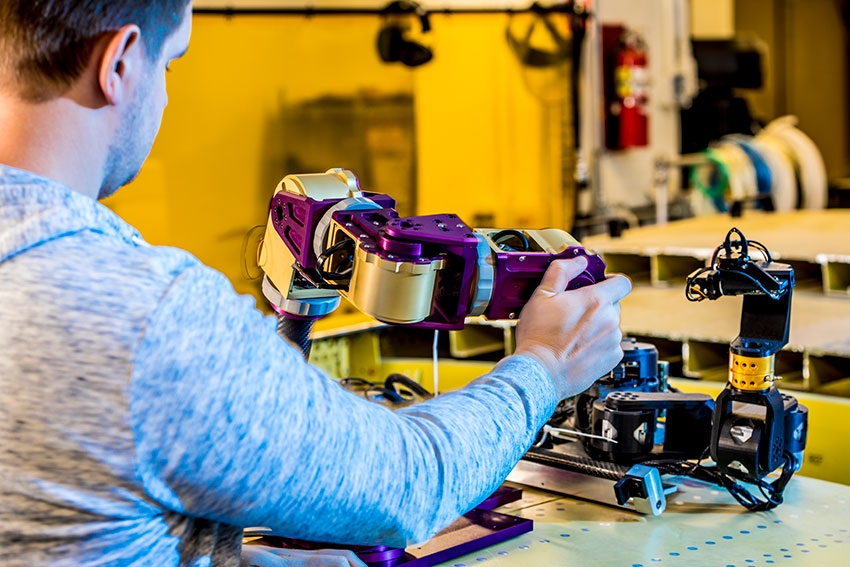

- Robotics and human interaction

- Self-assembly manufacturing

Research highlights

Boeing Advanced Research Collaboration pairs Boeing engineers with students and faculty to develop solutions for Boeing products in the areas of automation, robotics, composites and aircraft assembly.

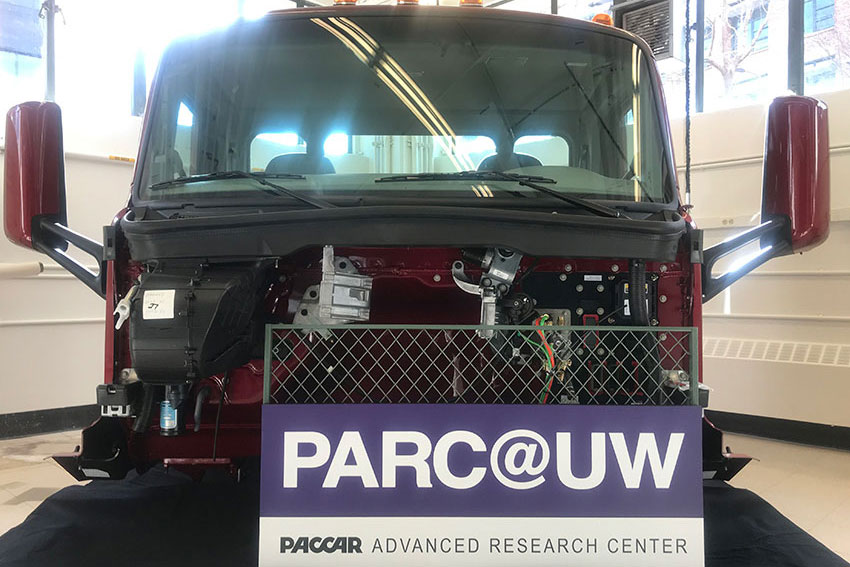

PACCAR Advanced Research Center provides a lab for PACCAR-sponsored capstone projects with goals of expanding into a collaborative research space for students, faculty and PACCAR engineers.

The Washington Clean Energy Testbeds accelerate the development, scale-up and adoption of new energy technologies by providing labs for prototype manufacturing, testing and systems integration.

A consortium of academic institutions, aerospace companies and government agencies, the Center for Advanced Materials in Transport Aircraft Structures seeks solutions to the challenges associated with the application of composites and advanced materials for large commercial aircraft.

Award-winning student teams

Formula Motorsports designs, builds and competes small formula-style racecars from scratch. The team has had years of success with combustion vehicles and now focuses on electric.

UW Hyperloop designs, fabricates and competes small-scale pods that travel by magnetic levitation inside tubes at SpaceX headquarters.

WOOF 3-D Print Club provides emerging engineers with an environment centered on additive manufacturing.